Oil Free Gas Compressors for Liquid Transfer

Product Details:

- Product Type Gas Compressor

- Technics requirement based

- Material requirement based

- Metal Type Color Steel

- Application Industrial

- Size requirement based

- Weight requirement based Pound (lb)

- Click to view more

Oil Free Gas Compressors for Liquid Transfer Price And Quantity

- 1 Piece

Oil Free Gas Compressors for Liquid Transfer Product Specifications

- Color Steel

- Gas Compressor

- requirement based

- requirement based Pound (lb)

- requirement based

- requirement based

- Industrial

Oil Free Gas Compressors for Liquid Transfer Trade Information

- requirement based

- 100 Piece Per Day

- 1 Days

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- Australia, North America, Eastern Europe, Western Europe, Central America, Middle East, South America, Asia, Africa

- All India

Product Description

Product Type

Gas Compressor

Metal Type

Color Steel

Application

Industrial

Main Export Market(s)

Australia, North America, Eastern Europe, Western Europe, Central America, Middle East, South America, Asia, Africa

Main Domestic Market

All India

Delivery Time

1 Days

Supply Ability

100 Per Day

Specification

Compressor Technology

Reciprocating Compressor

Horse Power

5 HP

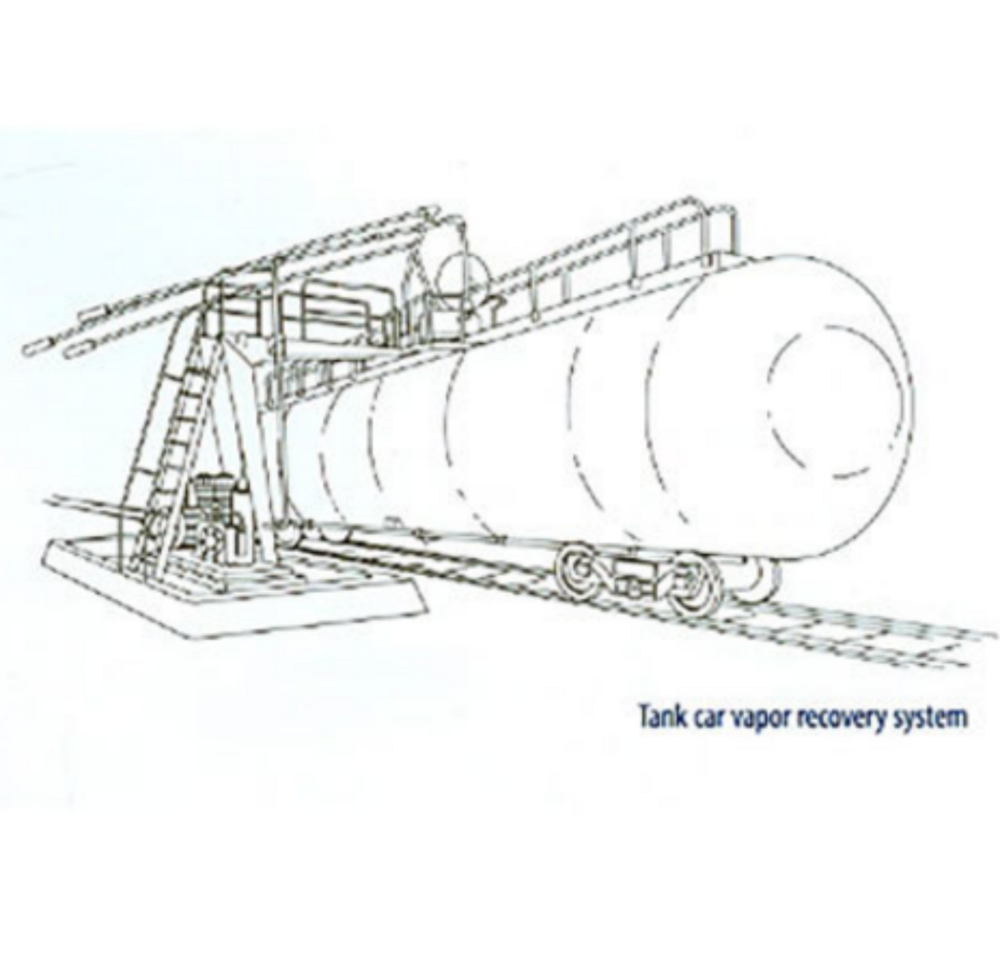

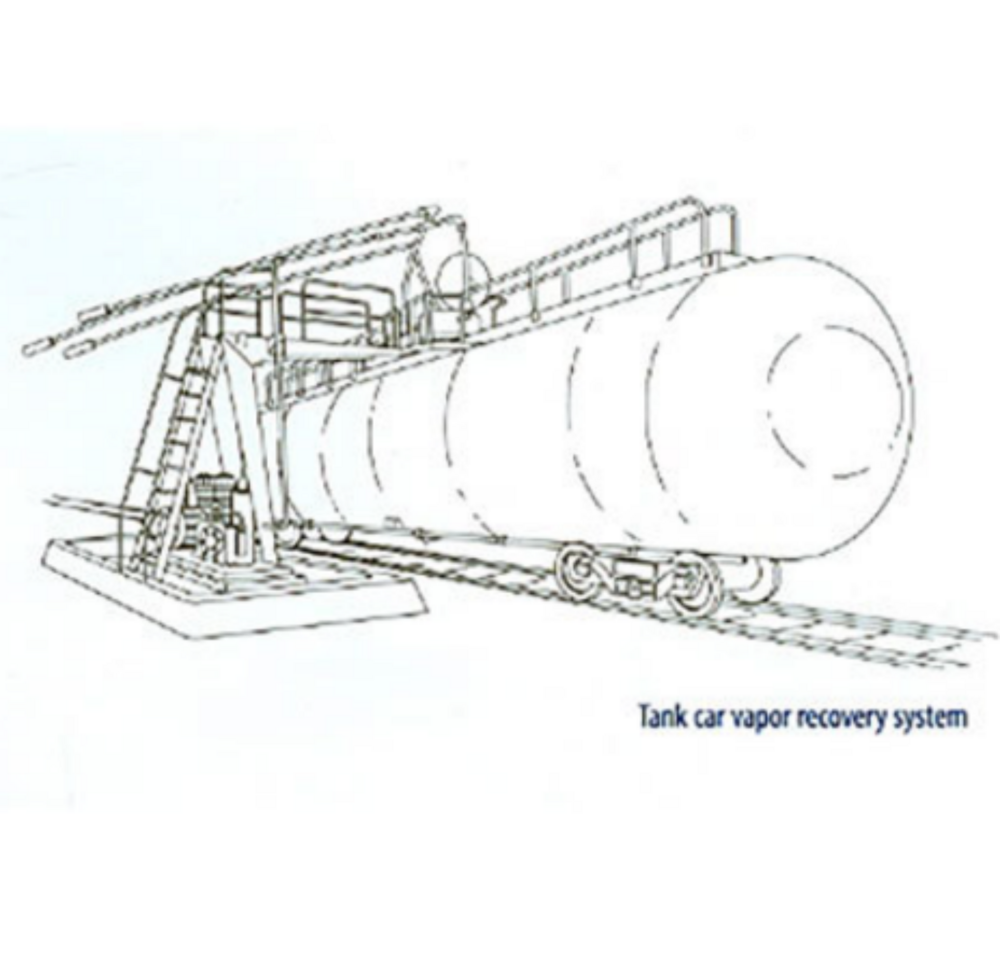

Oil Free Gas Compressors for Liquid Transfer

More Similar Oil Free Gas Compressors for Liquid Transfer

Pump Unit Set

Price: 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Pump Unit Set

Application:Industrial

Material:metal

Product Type:Pump Unit Set

Size:requirement based

Technics:requirement based

Know More

Send Inquiry

Get Latest Price

LPG Vaporizer

Price: 5000 INR / Piece

Minimum Order Quantity : 1 Piece

LPG Vaporizer

Application:Industrial

Material:nil

Metal Type:Other

Product Type:LPG Vaporizer

Size:nil

Know More

Send Inquiry

Get Latest Price

Steam Heated Vaporizers

Price: 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Steam Heated Vaporizers

Application:Industrial

Material:nil

Metal Type:Stainless Steel

Product Type:Steam Heated Vaporizers

Size:nil

Know More

Send Inquiry

Get Latest Price

LPG Loading Arms

Minimum Order Quantity : 1 Piece

LPG Loading Arms

Application:Industrial

Metal Type:Other,

Product Type:LPG Loading Arms

Know More

Send Inquiry

Get Latest Price

LPG Propane Ammonia Vaporizers

Price: 150000 INR / Unit

Minimum Order Quantity : 1 Piece

LPG Propane Ammonia Vaporizers

Application:Industrial

Material:nil

Metal Type:Stainless Steel

Product Type:LPG Propane Ammonia Vaporizers

Size:nil

Know More

Send Inquiry

Get Latest Price

Zimmer Vaporizer

Price: 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Zimmer- Vaporizer

Application:Industrial

Material:nil

Metal Type:Other

Product Type:Zimmer Vaporizer

Size:nil

Know More

Send Inquiry

Get Latest Price

Share a Quick Message with us

Get Quotation

Get Price List

Discuss Requirement

Enter Buying Requirement Details

Mobile number

call

Send Inquiry

Specification

|

Compressor Technology |

Reciprocating Compressor |

|

Horse Power |

5 HP |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+