Circulating Hot Water Vaporizer

Product Details:

- Technics nil

- Product Type Circulating Hot Water Vaporizer

- Material nil

- Metal Type Steel

- Application Industrial

- Size nil

- Weight nil Grams (g)

- Click to view more

Circulating Hot Water Vaporizer Price And Quantity

- 1 Piece

Circulating Hot Water Vaporizer Product Specifications

- nil

- Circulating Hot Water Vaporizer

- nil

- nil Grams (g)

- nil

- Steel

- Industrial

Circulating Hot Water Vaporizer Trade Information

- nil

- Cash in Advance (CID)

- 100 Piece Per Week

- 1 Week

- Sample costs shipping and taxes has to be paid by the buyer

- poly pack

- All India

Product Description

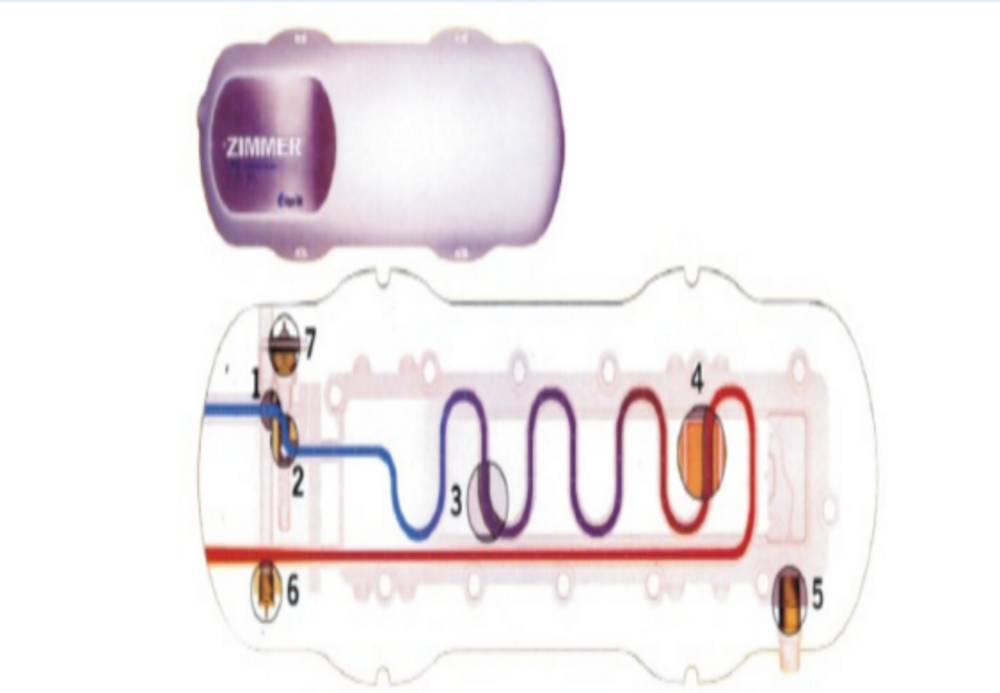

Leveraging on our vast industry experience, we are offering our clients a finest quality range of Circulating Hot Water Vaporizer that is used to vaporize cryogenic fluids. The manufacturing process of this vaporizer is carried out according to the set industry standards using best grade raw material with the help of latest technology. It can be used elsewhere in the plant and is added to an existing water system. Moreover, this Circulating Hot Water Vaporizer is available in various specifications as per the requirements to customers.

Circulating Hot Water Vaporizer is acknowledged for its 100% turn down capability. All the exposed metal parts in the vaporizer are mechanically cleaned, primed and painted for durability. These are manufactured by our skilled team using quality approved materials and modern techniques keeping in mind predefined industry standards. Apart from this, the product is available in various specifications to clients at nominal prices.

Features :

- 100% turn down capability.

- Both LPG and hot water fabrication are stamped in accordance with ASME.

- Explosion Proof configuration meets Class I, Division 1, Group D as defined by NFPA pamphlet 70.

- Factory Mutual (FM) approved.

- Two safety devices to ensure dry superheated vapor.

- Bayonet style tubes allow stress-free expansion unlike other designs.

- Fully insulated for maximum thermal efficiency.

- Ready to connect to plant facilities.

- Strainer included.

- Stainless steel outer heat exchanger tubes standard.

- LPG pressure vessel is fabricated in accordance with ASME Pressure Vessel Code, Section VIII, Division 1.

- LPG pressure vessel rating: 250 PSIG at 650? F (17.6 Kg/Cm2 at 343? C).

- U.L. stamped external relief valve: 250 PSIG (17.6 Kg/Cm2).

- Factory Mutual (FM) approved.

- All wiring, controls, electrical components and their installation comply with recognized code standards defined in NFPA pamphlet 58 and NFPA pamphlet 70.

- Explosion Proof configuration meets Class I, Division 1, Group D as defined by NFPA pamphlet 70.

- Pressure balanced LPG supply/delivery operation.

- Two safety devices to prevent liquid carryover -low vapor temperature switch and high liquid level switch.

- Inlet safety solenoid valve.

- All exposed metal surfaces are mechanically cleaned, primed and painted.

Product details

|

LPG pressure vessel rating |

250 PSIG at 650 F (17.6 Kg/Cm2 at 343 C). |

|

stamped external relief valve |

250 PSIG (17.6 Kg/Cm2) |

|

Turn down capability |

100% |

|

Automatic Grade |

Automatic |

|

Design |

Standard |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+