Gas Leak Check Valve

Product Details:

- Product Type Gas Leak Check Valve

- General Use Industrial

- Material

- Type Gas LeakValve

- Purity(%) requirement based

- Production Rate requirement based

- Dew Point requirement based

- Click to view more

X

Gas Leak Check Valve Price And Quantity

- 1 Piece

Gas Leak Check Valve Product Specifications

- requirement based

- Gas LeakValve

- requirement based

- requirement based

- Gas Leak Check Valve

- requirement based

- Industrial

Gas Leak Check Valve Trade Information

- requirement based

- 1 Piece Per Week

- 2-10 Week

- Sample costs shipping and taxes has to be paid by the buyer

- no pack

- All India

Product Description

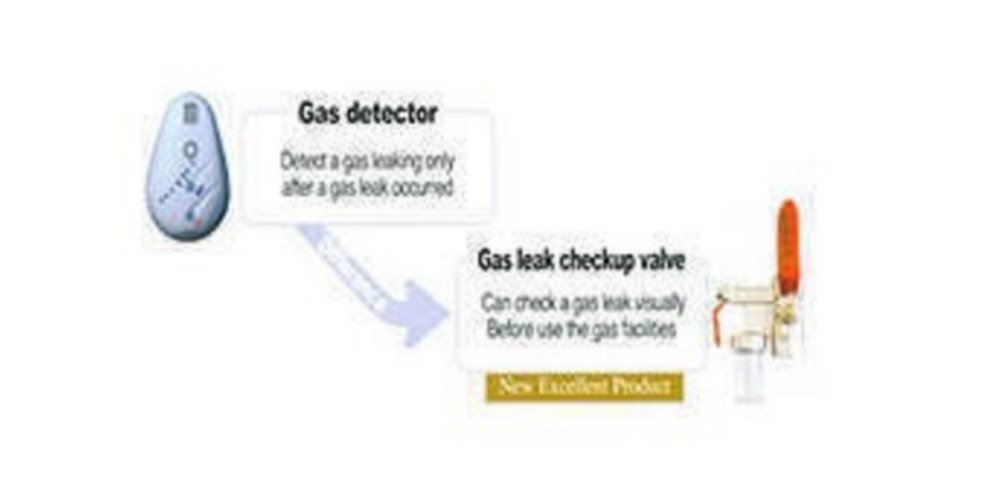

Gas Leak Check ValveWe are a noteworthy manufacturer, exporter and supplier of premium quality Gas Leak Check Valve that is suitable for checking liquid, discharge, steam, air, water, oil suction and hot gas lines. Due to its easy to open and close with a very low differential pressure, this valve is highly demanded in the market. This valve is used for unidirectional flow in liquid line having low temperature applications. The offered Gas Leak Check Valve is manufactured with utmost precision using finest grade raw material with the help of advanced technology.

Features:

-

High strength

-

Precise design

-

Sturdy construction

-

Fine finish

Specifications:

| Model | XP 311 alpha A |

| Detection Principle | Catalytic combustion sensor. |

| Minimum Detectable Leak Rate | 0.5% LEL |

| Measuring Range | 0 to 10% LEL and 0 to 100% LEL combustibles. |

| Calibrating Gas | LP (iso-butane) or methane. Calibration for other specific gases is available on request. |

| Accuracy | +- 5% of full scale reading |

| Response Time | Within 3 seconds (90% of final reading). |

| Alarm Style and Preset Point | Intermittent tone and flashing lamp 20% LEL preset, but available at other point on request. (not in XP 311). |

| Operating Temperature | -20 Deg C to +50 Deg C (-4 Deg F to +122 Deg F). |

| Power Source | Size AA dry (1.5V x 4pcs). |

| Battery Life | 100 intermittent tests of 3 minutes duration each or 4 hours for continuous operation using dry . |

| Dimensions | 190 mm x 84 mm x 40 mm. |

| Weight | 700 gr. (1.5 lbs.) |

| Standard Accessories | Non-conductive probe with filter/moisture trap. 1 meter long sampling hose. Carrying case with shoulder strap. Set of four size AA dry . Two filter elements. |

| Optional Accessories | Sampling tube 5m long or as required. Floating Probe with float and filter/moisture trap. Telescopic probe. Flexible probe. Remote alarm unit (BEZ-1) with 10m long cable |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email