Flange Mounted Pumps for Bobtails and Transports

Product Details:

Flange Mounted Pumps for Bobtails and Transports Price And Quantity

- 13000 INR/Piece

- 1 Piece

Flange Mounted Pumps for Bobtails and Transports Trade Information

- Per Week

- 2-10 Week

Product Description

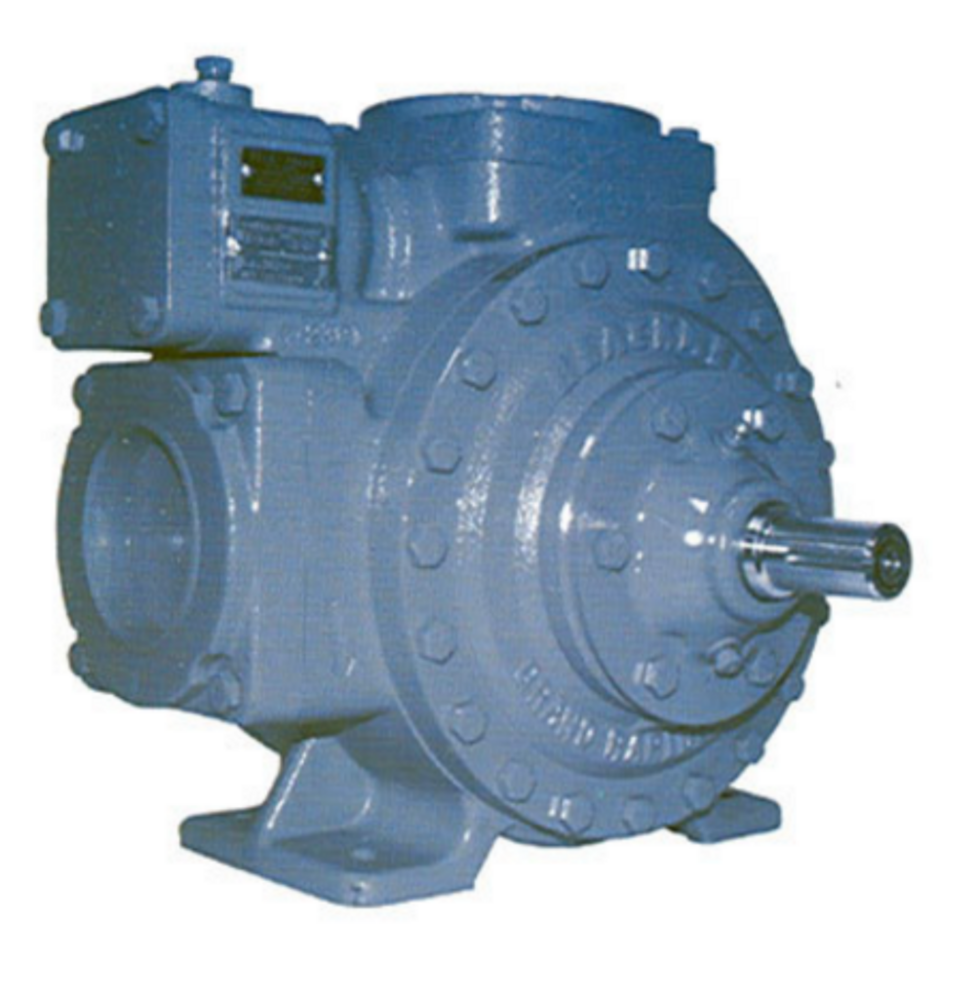

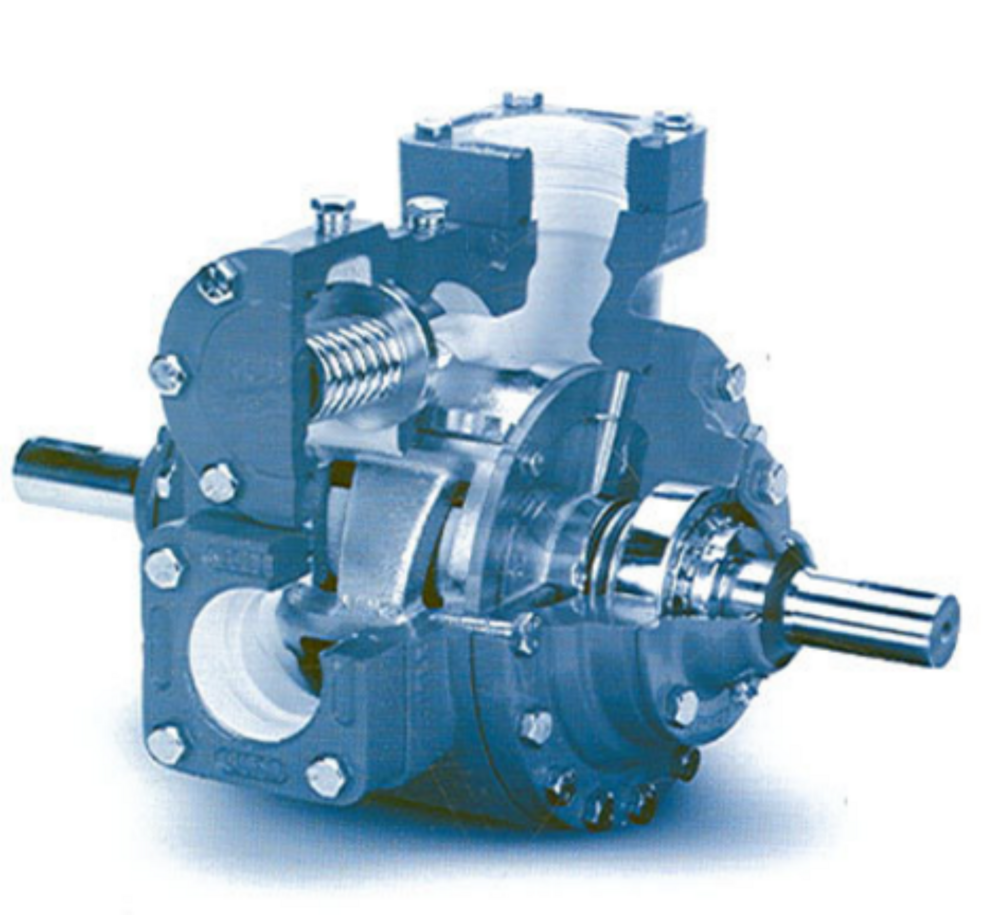

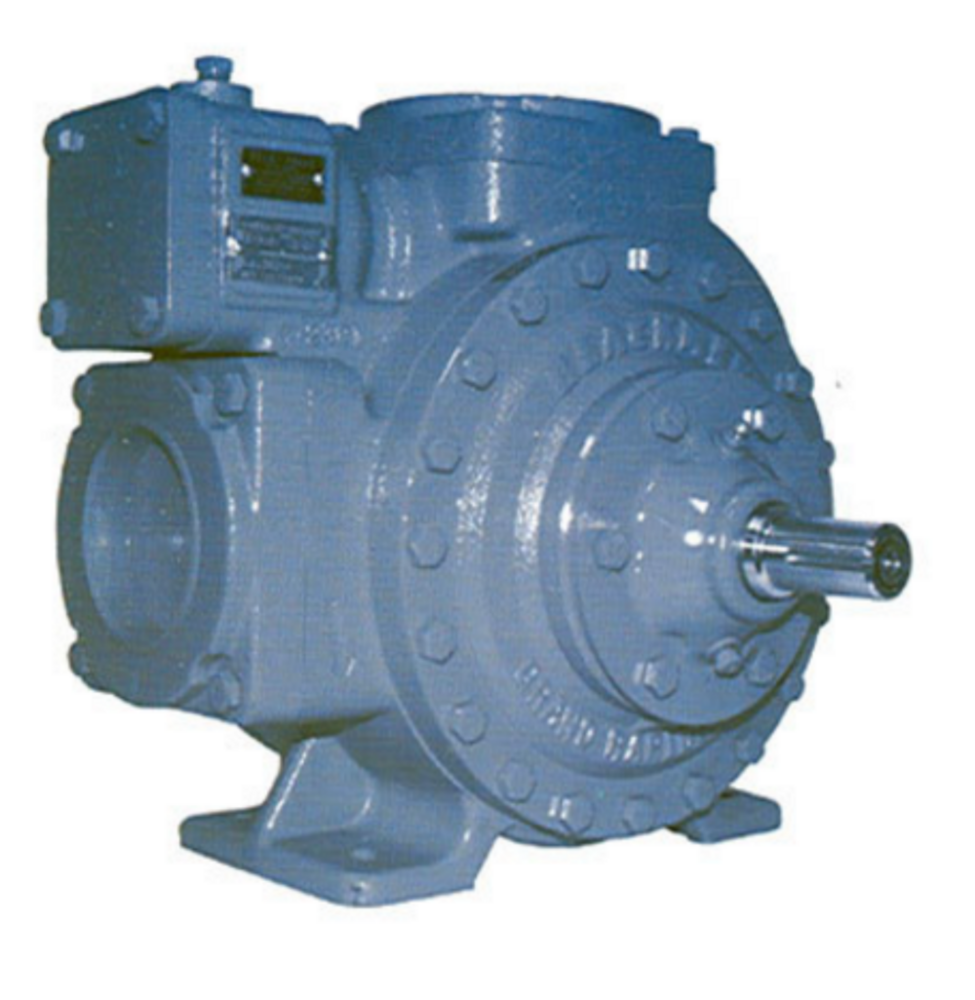

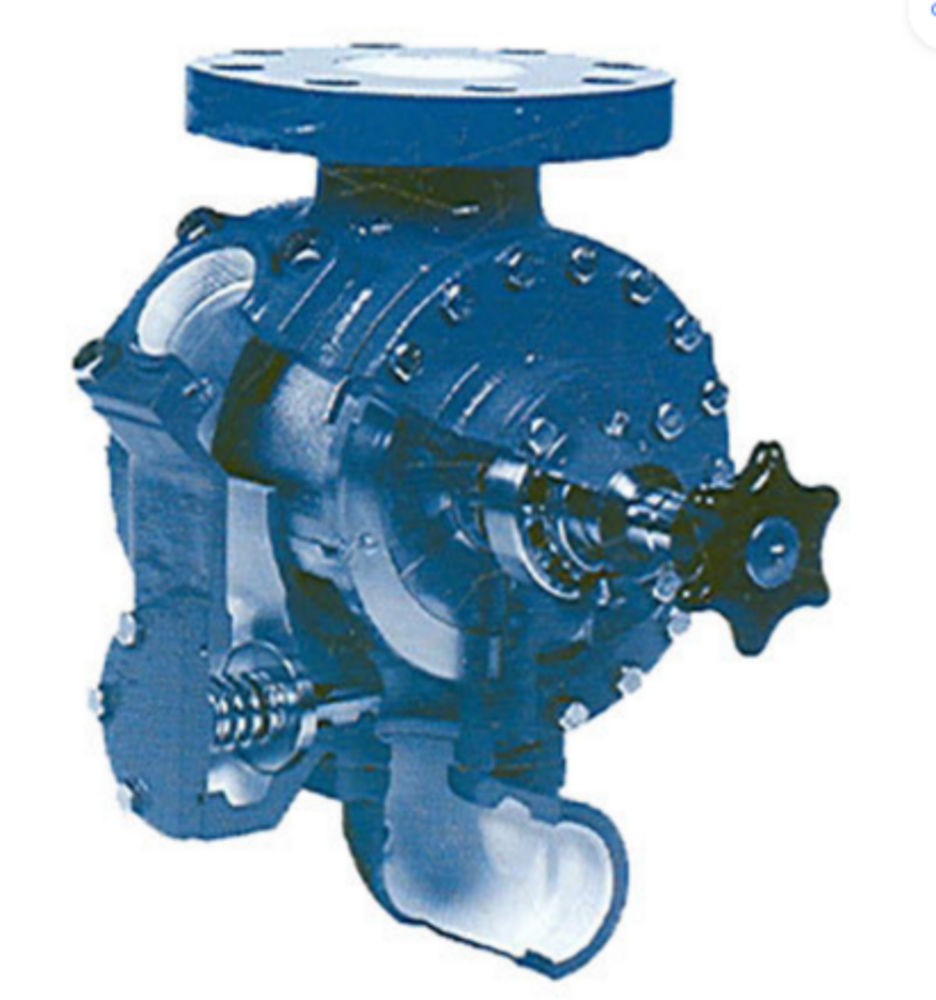

Blackmer TLGLF3 and TLGLF4 pumps are designed to flange mount directly to a commercial internal control valve in combination with the tank of a bobtail or transport Direct mounting eliminates the need for inlet pipes shutoff valve and external strainer which can restrict flow and cause vaporization problems The result is smoother operation and longer pump life

Both models are equipped with a doubleended drive shaft for clockwise or counterclockwise rotation by simply changing position of the pump Each model also has an auxiliary intake port which can be used for emergency unloading of another tank or transport In addition these pumps have an internal relief valve patented cavitation suppression liners to reduce noise vibration and wear

Standard construction materials for both models include BunaN mechanical seals and Duravanes for handling both LPgas and anhydrous ammonia The casing liner and end discs are replaceable for easy rebuilding of the pumping chamber if ever necessary

The TLGLF3 is widely used on bobtails because of its compact mounting arrangement with a 3inch ANSI intake flange and 2inch auxiliary intake and discharge ports Capacities range from 60 to 129 US gpm 227 to 488 Lmin

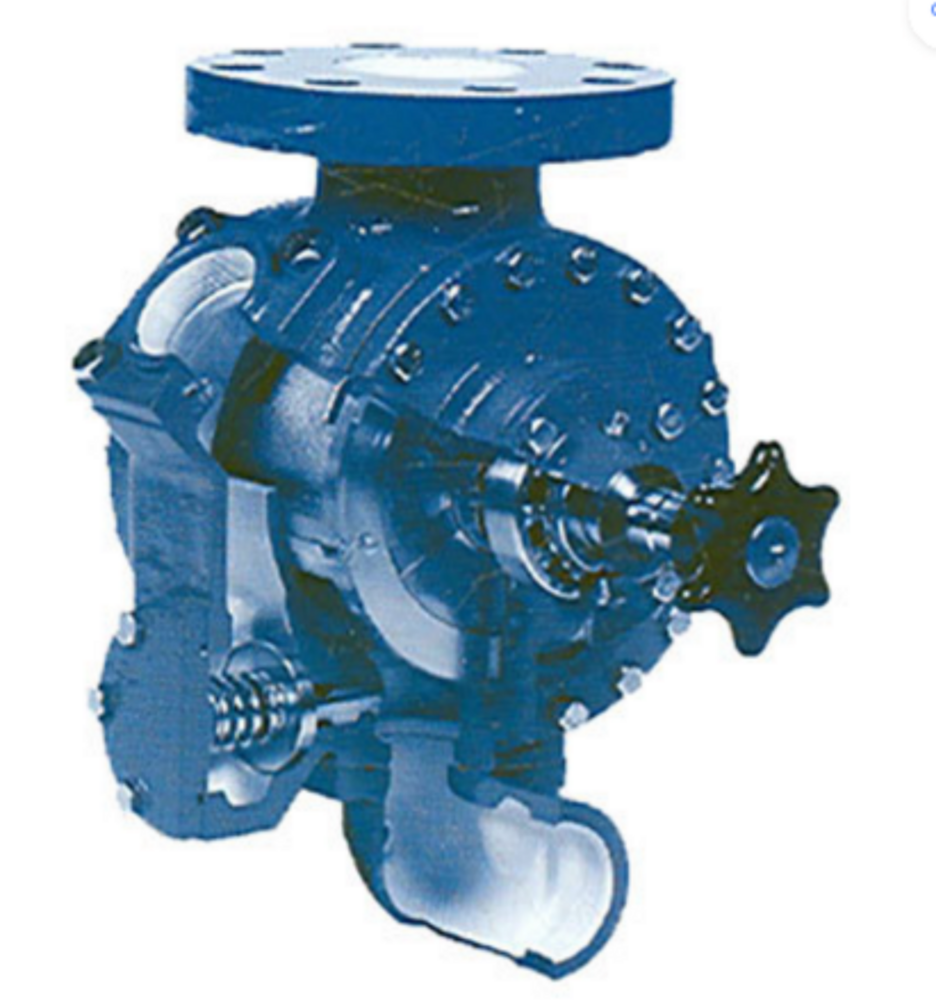

The TLGLF4 offers maximum output rates and fast turnaround time for transports It is designed with 4inch ANSI intake flange a 3inch auxiliary intake port and twin 2inch discharge ports which permit the use of two hoses if necessary to reduce pressure loss when unloading into restrictive receiving systems Capacities range from 200 to 350 US gpm 757 1325 Lmin Maximum differential pressure for both models is 125 psi 862 Bar

Hydraulic Drive Packages

Blackmer 2inch through 4inch pump models are offered with complete factory engineered hydraulic drive packages Blackmer highly recommends the use of hydraulic drive systems to maximize pump performance and extend equipment life especially on truck mounted bobtail and transport pumps

The Blackmer Hydrive cooler by Mouvex a Dover company forms the heart of a hydraulic drive system and offers up to 26 horsepower 194 kW of actual heat dissipation The Hydrive has a compact design with stainless steel It protects the system during cold startup allows for remote system onoff control and provides both system cooling and monitoring of oil filtration

A typical hydraulic drive package includes a PTO hydraulic pump Hydrive cooler cargo pump control valve speed control valve hydraulic motor and mounting hardware Hydraulic motor adaptor kits are also available to retrofit existing Blackmer LP gas pumps for hydraulic drive operation

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+